WORLD LEADER IN INDUCTION HEATING SYSTEMS, POWER SUPPLIES & ELECTRIC GLASS MELTING SYSTEMS

Interpower Induction is a single-source manufacturer of turn-key induction heating systems, power supplies and electric glass melting and reheating equipment. We provide our customers with unique testing capabilities prior to installation of our products. Interpower Induction systems are used in automotive, forging, melting, aerospace, glass works, nuclear, heavy machinery, railroad, construction, technology, food and beverage, and medical device industries. We have a dedicated machine shop that offers a small to large batch CNC machining facility and our unique in-house manual assembly fixture manufacturing service.

Applications

Interpower Induction also offers a wide range of electric glass melting and re-heating equipment. This range was introduced to improve output whilst vastly reducing running costs and the industries carbon footprint.

Products

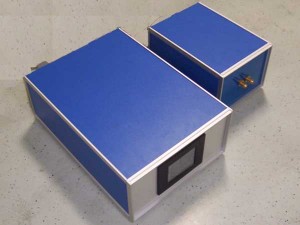

Interpower Induction is the world leading supplier and developer of Zone Control Technology® and induction heating equipment. We support products which include power supplies, coils, material handling, water cooling systems, fluid and gas heaters, bowl feeders, and our proprietary Sign-Link™ quality monitors. We develop induction heating systems to meet your company’s unique project needs.

We have developed the electric Raden and Ego range to replace legacy gas fuelled glass melting and re-heating equipment. We have a furnace size and capacity to fit your companies requirements. Our Raden furnaces are able to be remotely monitored and controlled for ultimate management of your operation.

What is Induction Heating?

Induction heating is a fast, efficient and non-contact method for heating conductive materials such as metals and semiconductors by applying an alternating magnetic field. It has quickly become the preferred heating technologies for industrial applications due to its advantages over traditional heating techniques (resistance heating, flame heating, ovens, furnaces, etc.). Induction heating is particularly useful for performing highly precise or repetitive operations.

Interpower Induction uses this method for heating applications across a multitude of industries. How does this method differ from other heating processes?

To the typical engineer, induction is a fascinating method of heating. Watching a piece of metal in a coil turn cherry red (watching materials heat quickly without a flame) in a matter of seconds can be surprising to those unfamiliar with induction heating. Induction heating equipment requires an understanding of physics, electromagnetism, power electronics and process control, but the basic concepts behind induction heating are simple to understand.

Clean Energy

Induction systems are electrically powered with no fossil fuels. This power may be produced from environmentally sustainable energy such as wind, hydro, and solar power.